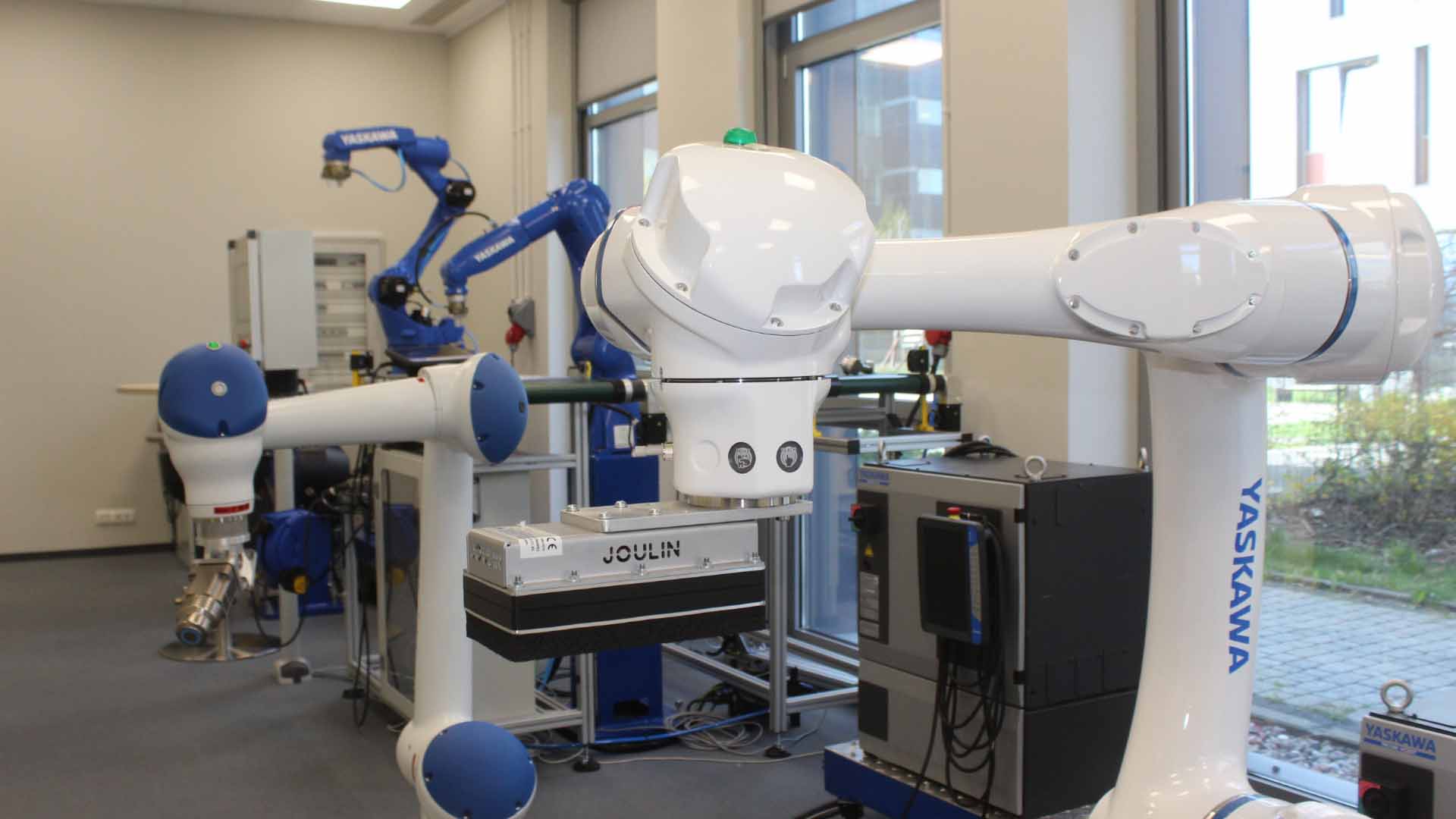

Cobot MOTOMAN HC20DT IP67

Yaskawa Polska

MOTOMAN HC20DT IP67 is a 6-axis collaborative robot with a payload of 20 kg. The operator's safety is ensured by the Power and Force Limit technology, which enables the robot to stop automatically in the event of contact with a human being. Thanks to this, the robot can work hand in hand with the operator without the need for fencing. The robot's movements can be easily programmed manually by guiding the arm from point to point.

- Robotics, Control, Drive technology

Go to:

Description of innovation

MOTOMAN HC20DT IP67 is a 6-axis collaborative robot with a payload of 20 kg. Operator safety is ensured by the Power and Force Limit technology, which allows the robot to automatically stop in the event of contact with a human being. Thanks to this, the robot can work hand in hand with the operator without the need for fencing. The robot’s movements can be easily programmed manually by guiding the arm from point to point. The individual positions of the arm and gripper are saved by pressing the “Teach” and “Tool” buttons, which significantly reduces programming time. The arm geometry has been designed so that there are no pinch points in it, which allows you to maximize the protection of the person (fingers). MOTOMAN HC20DT is adapted to work without additional protection, such as fencing, which significantly reduces the costs and time of commissioning the installation. However, the decision to do so should be preceded by a thorough risk assessment. What distinguishes the HC20DT IP67 are not only the unique technical parameters, but also extensive safety functions, which, in combination with three safety scanners integrated with the palletizing station, allow it to safely work with people without the need for additional security.

Application

The main task of the HC20DT IP67 is taking boxes from the conveyor and stacking them on a pallet. To maximize the precision of the operation, the process uses a suction mat type that allows the transport of packages of various sizes. The gripper is also great at carrying paper sheets used to separate individual layers on a pallet.

Thanks to the direct coupling of the robot controller and the palletizing station as well as the advanced mathematical algorithms of the control system, the operation of the application does not require specialist programming knowledge. The movements of the robot can be easily programmed using the intuitive HMI made by Biuro Inżynierskie IEC or using the Yaskawa Smart Pendant programmer or the “Hand Guiding” function, ie by guiding his arm from point to point.

The HC20DT IP67 lifting capacity and range make it perfect for all Pick & Place and palletizing applications, but not only: thanks to advanced safety functions and intuitive programming, it can also be successfully used in a number of other applications.

Cooperation model

In order to establish cooperation, please contact the representative of Yaskawa Polska.

Yaskawa Polska

Yaskawa was founded over 100 years ago in Japan as a manufacturer of electric motors that has grown over the years to be a technological leader in the robotics and industrial automation industry. The company boasts sales of EUR 3.8 billion and employment of 14,500 qualified and passionate employees around the world. The official branch of Yaskawa Polska Sp. z o.o. was established in 2016 in Wrocław, although our robots (known under the MOTOMAN brand) had been operating on our domestic market much earlier. Our products drive many well-known industries and enterprises, thanks to which our brand becomes one of the most recognizable in Poland in the field of robotization and automation. As a global company, Yaskawa has been ranked among the 100 most innovative companies in the world for 5 years!

- Industry

- ul. Duńska 11, 54-427 Wrocław

- www.yaskawa.pl

- info.pl@yaskawa.eu.com

- +48 71 792 86 70

Contact us about our innovation

Paulina Wessely

brak danych

- brak danych

- paulina.wessely@yaskawa.eu.com